Heat Prevention: How to Keep Your Workforce Safe During a Historically Hot Summer

Time to Embrace the Heat

The Impact of Heat in the Work Environment

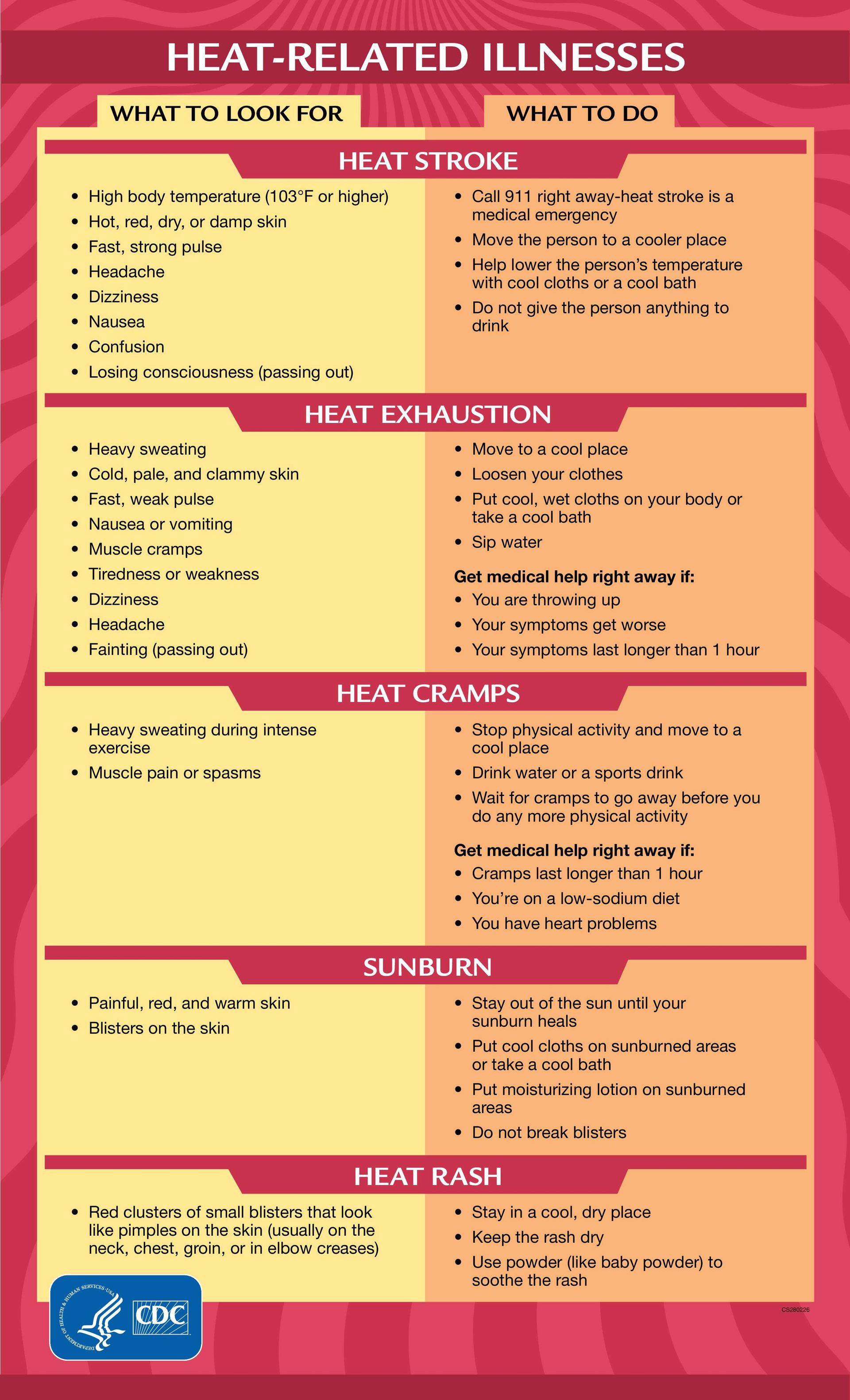

Uncontrolled heat exposure has direct and indirect effects. Direct effects include heat stroke, heat exhaustion, heat cramps, heat rashes, or death, while indirect effects involve weakened psychomotor skills and a temporary decline in cognitive function. These indirect effects are often overlooked, and can lead to an unsafe work environment and an increase in OSHA recordables.

“Heat can increase workers’ risk of injuries, as it may result in sweaty palms, fogged-up safety glasses, dizziness, and may reduce brain function responsible for reasoning ability, creating additional hazards” says the NIOSH

Criteria for a Recommended Standard: Occupational Exposure to Hot Environments.

Let’s paint an example. John is a forklift operator at a large distribution center that lacks adequate air conditioning. During the summer months, temperatures reach up to 95°F.

While moving a pallet, John becomes fatigued from heat exposure and zones out. When he snaps back into it, he realizes he is on a collision course with another operator. Trying to redirect his trajectory, John quickly veers the forklift in the opposite direction. However, his fogged-up glasses prevent him from noticing a nearby storage rack. John strikes the rack, causing several heavy boxes to fall. One of the falling boxes strikes John's co-worker on the shoulder, causing an OSHA recordable injury.

As you can see, the indirect effects of heat can be just as troublesome as the direct effects. A new study by WCRI showed that “compared to temperatures between 65 and 70 degrees, the overall number of work-related injuries increased between 5% and 6% when the daily maximum temperature rose above 90 degrees” (Laman 2024).

Heat’s impact in the work environment is significant, and it’s important to take preventative measures to limit the direct and indirect effects of heat.

Preventative Measures

OSHA does not currently have a heat standard, meaning that heat related hazards fall under OSHA’s General Duty Clause. However, the Labor Department has been working on a heat standard since 2021, with support from the Biden Administration.

A white house official confirmed that “Penalties for heat-related violations in workplaces would increase significantly” under the standard.

Taking preventative measures now will help keep your workers safe while also preparing your business for what seems like an inevitable policy change.

There are three main categories of prevention:

Engineering Controls and General Guidelines:

In a controlled environment, heat stress can be managed through engineering controls. According to the NIOSH criteria, common controls include “increasing ventilation, bringing in cooler outside air, reducing the temperature of a radiant heat source, shielding the worker, and using air conditioning equipment.” Eliminating heat hazards from the work environment through engineering controls is a great first step.

Employees should also have constant access to water. NIOSH recommends drinking one eight ounce cup of water every 15-20 minutes on hot days. If an employee is going to be sweating for several hours, employers should provide electrolyte water.

Heat stress can also be managed by providing added rest periods for employees. Designated rest periods will eliminate prolonged heat exposure and allow workers to cool down, hydrate, and check on one another.

Lastly, new employees are at the highest risk for heat illness. By following CDC guidelines on heat

acclimatization, managers can safely build up an employee's heat tolerance.

Pre Placement Medical Examinations:

Although most workers will respond well to acclimatization, some may be heat intolerant. While there is no specific test performed for heat tolerance, requiring a pre-placement physical for employees who will be exposed to the heat is the most effective way to assess their personal risk.

A pre-employment (or pre-placement) physical allows a physician to thoroughly review your employee’s medical history, identify potential risk factors like dizziness, diabetes, or obesity, ask about prior problems with heat exposure, and order any recommended additional testing.

Ironbound Medical Services has been providing thorough

pre-placement physical exams for over 15 years in the Newark, NJ area.

When asked about the importance of pre-placement physicals for employers, IMS Medical Director Robert Mustillo said:

“Pre-placement exams are always a good idea for companies. We work with clients to assess which part of their workforce requires a physical and which components of a physical should be included, helping them prevent future workplace incidents at an affordable cost. In the long run, employers will save significantly on workers’ comp costs by screening out candidates who are at increased risk of problems like heat stroke, heart attacks, or cerebrovascular accidents while performing physical labor. Additionally, your employees will be able to rest assured that they are physically fit to perform their job, creating a new peace of mind for your workforce.”

To make sure your employees are receiving a thorough pre-employment physical, we recommend that you look for a facility that only staffs board-certified physicians. Physical examinations require experience and expertise, and despite this, many providers utilize lesser trained nurse practitioners and physician assistants.

Health and Safety Training:

You’ve introduced engineering controls and a heat protocol to your workplace. You’ve sent your employees to the company doctor to ensure they are physically fit to perform their job. Now it’s time to train your workforce on the signs and symptoms of heat injury.

The following

chart from the CDC provides the symptoms and appropriate response to different heat-related illnesses.

Employees should also be trained on proper hydration, what to wear, the importance of acclimatization, and the effect drugs, alcohol, caffeine, obesity, and diabetes can have on heat tolerance.

NIOSH also points out that many workplaces may need to

shift their cultural attitude toward heat stress. Workers may believe that they develop an immunity to the heat over time and stop consuming ample fluids or taking breaks. They also may believe they can train themselves to tolerate heat by intentionally denying fluids. Both of these behaviors are risky and must be discouraged through education.

Wrapping Up

In the next couple of years, we can expect rising temperatures to continue, and a federal workplace heat policy to be established. Employers need to prepare accordingly.

This starts with understanding that heat impacts the workplace both directly (through heat related illnesses) and indirectly (a decline in psychomotor or cognitive related tasks).

To eliminate heat related injuries, employers must protect workers by utilizing engineering controls, encouraging hydration, mandating safety breaks, and introducing acclimatization periods.

Pre-employment physicals are highly recommended to ensure a job candidate will be able to perform the physical component of their role, and will help to identify any issues a candidate may have with heat exposure.

Lastly, health and safety training will ensure your workers are well equipped to recognize the risk factors and side effects associated with heat related illness.

For employers looking to learn more about current heat exposure guidelines, please use the following link:

https://www.cdc.gov/niosh/docs/2016-106/pdfs/2016-106.pdf?id=10.26616/NIOSHPUB2016106

For employers local to the Newark, NJ area, learn more about our services at

https://www.ironboundms.com/